Les batteries Li-Ion

Où s’en procurer au moindre coût ?

Dans les containers de piles usagées. Ça va du pack de batterie d’ordinateur à la batterie de téléphone portable.

Par ailleurs, il n’est pas possible de s’en procurer individuellement à l’état neuf. Le prétexte invoqué est la dangerosité des batteries Li-Ion. Cette dangerosité est avéré lorsque la batterie est exposée à des conditions extrêmes c’est à dire court-circuit ou surcharge à forte intensité et à plus de 4,5 V par éléments. Ce qui n’est pas le cas ici !

Qu’en faire ?

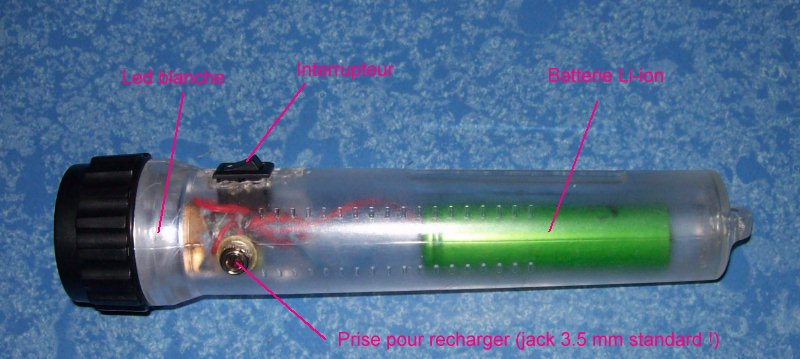

Ces batteries peuvent être réutilisées pour de l’éclairage portatif (voir les exemples tout en bas de cette page). Couplées avec des led blanches, l’autonomie est remarquable. Les led proviennent soit de lampe torche de piètre qualité soit de bornes solaires usagées que l’on peut repérer dans un container à appareils électroniques à l’entrée des grandes surfaces. On pensera à monter en série une résistance de 15 ohms 1/4 W afin de limiter le courant à 20 mA par led.

Comment charger un batterie Li-Ion ?

Tout d’abord, pas besoin d’un chargeur de compétition à microprocesseur. Pour charger une élément Li-Ion, il faut l’amener à une tension finale de 4,1 - 4,2 V. Pour ce faire, on utilise une tension de +5V, disponible soit au bout d’une sortie d’un port USB soit issue d’un régulateur tripode de type 7805. Cette tension sera diminuée de 0,7 à 0,8 V en montant en série une diode de type 1N400X (1N4001 à 1N4007). Les moins téméraires pourront se procurer des chargeurs individuels (voir dx.com sku 13820)

N’y-a-t-il pas un risque d’explosion ?

J’ai rechargé de nombreuses fois des pack de Li-Ion par cette méthode, et je n’ai pas eu à déplorer ce type d’accident. Il semblerait que les batteries Li-Ion explosent lorsqu’elles sont surchargées. En effet, pour charger rapidement des batteries Li-Ion, il faut dépasser la tension de 4,3V et surtout l’interrompre à la fin de la charge. Tant que l’on reste en dessous, rien de fâcheux ne peut se produire.

Conclusion

Après avoir collecté plusieurs pack de batterie d’ordinateur portable, j’ai pu constater que tous sans exception, étaient construits à partir d’éléments rond de 18 mm de diamètre et de 67 mm de long, les fameux 18650 disponibles au détail sur les sites chinois comme Deal Extreme (dx.com). On aura compris que si les éléments ne sont pas interchangeables, c’est uniquement dans le but d’obliger les consommateurs de changer l’ensemble du pack alors qu’il est hautement probable que seul 1 des 8 éléments est défaillant.

Nous avons affaire à un complot "d’obsolescence programmée". La durée de vie des batterie Li-Ion est écourtée volontairement par les constructeurs pour maintenir artificiellement un marché. Explication : au lieu d’opérer le remplacement d’un seul élément, tout le pack est à changer. Celui-ci est vendu à un tarif suffisamment exorbitant pour le consommateur renonce au remplacement et préfère acquérir un nouvel appareil avec une batterie neuve. C’est tout bénéfice pour les constructeurs d’ordinateurs et les fabricants de batteries Li-Ion.

http://batteryuniversity.com/learn/article/building_a_lithium_ion_pack

Building a Lithium-ion Pack

Reputable battery manufacturers do not supply lithium-ion cells to uncertified battery assemblers. This precaution is reasonable when considering the danger of explosion and fire when charging and discharging a Li-ion pack beyond safe limits without an approved protection circuit.

Authorizing a battery pack for the commercial market and for air transport can cost $10,000 to $20,000. Such a high price is troubling when considering that obsolescence in the battery industry is common. Manufacturers often discontinue a cell in favor of higher capacities. The switch to the improved cell will require a new certification even though the dimensions of the new cell are the same as the previous model.

Cell manufacturers must comply with their own vigorous cell testing and we ask, “Why are additional tests required when using an approved cell ?” The cell approvals cannot be transferred to the pack because the regulatory authorities do not recognize the safety confirmation of the naked cell. The finished battery must be tested separately to assure correct assembly and is registered as a standalone product. Read about Safety Concerns with Li-ion.

As part of the test, the finished battery must undergo electrical and mechanical assessment to meet the Recommendations on the Transport of Dangerous Goods on lithium-ion batteries for air shipment, rules set by the United Nations (UN). The electrical test stresses the battery by applying high heat, followed by a forced charge, abnormal discharge and an electrical short. During the mechanical test, the battery is crush-tested and exposed to high impact, shock and vibration. The UN Transport test also requires altitude, thermal stability, vibration, shock, short circuit and overcharge checks. The UN Transport works in conjunction with the Federal Aviation Administration(FAA), the US Department of Transport (US DOT) and the International Air Transport Association (IATA).*

The authorized laboratory performing the tests needs 24 battery samples consisting of 12 new packs and 12 specimens that have been cycled for 50 times. IATA wants to assure that the batteries in question are airworthy and have field integrity. Cycling them for 50 times before the test satisfies this requirement.

The high certification costs make many small manufacturers shy away from using Li-ion for low-volume products ; they choose nickel-based systems instead. While strict control is justified, an uncertified Li-ion kept in the hands of the expert and out of aircraft would be acceptable, but controlling such movement in the public domain is next to impossible. This makes it hard for the hobbyist who wants to win a race with a high-powered Li-ion battery but is bogged down by many rules.

With recurring accidents while transporting lithium-based batteries by air, regulatory authorities will likely tighten the shipping requirements further. However, anything made too cumbersome and difficult will entice some battery manufacturers to trick the system, defeating the very purpose of protecting the traveling public. Read about How to Transport Batteries.

* IATA (International Air Transport Association) works with airlines and air transport industry to promote safe, reliable, secure and economical air travel.

http://batteryuniversity.com/learn/article/how_to_transport_batteries

How to Transport Batteries

Many battery types fall under strict transportation regulation. This is done for the safety of those handling them and the passengers traveling on a common carrier. Here are the rules in short. Lead Acid

Most countries set strict rules for transporting lead acid batteries. Failure to comply with the regulations is a civil or criminal offense that can bring a stiff penalty on the carrier and/or shipper. The transport regulations require the following precautions.

The vehicle transporting batteries can carry only one type of hazardous material. Brace the batteries securely to prevent damage and short circuits in transit. Non-hazardous goods on the same vehicle must be secured to prevent damaging the batteries.

Batteries must be stacked upright, pole side outwards and placed on a wooden pallet. Place honeycomb cardboard between the layers and limit the stack to three layers on a single pallet. Wrap the package several times with shrink-wrap.

Identify hazardous material with labels marked “Corrosive” using the appropriate symbols and colors. Stickers must conform to regulatory specifications.

Mark all packages, i.e., batteries, wet, filled with acid, identification number (UN 2794).

Provide a bill of lading document that includes the name of the company and shipper, contents of package, description of hazardous material and shipper’s certification.

When shipping by air, restrict the weight per package to 25kg gross (55lb) on passenger air carriers. There is no limit on the number of packages per flight.

Different rules apply when shipping damaged batteries. A lead acid battery is considered damaged if there is a possibility of leakage due to a crack, or if one or more caps are missing. Transportation companies and air carriers may require that the batteries be drained of all acid prior to transport. Place damaged batteries in an acid-resistant container and add soda ash to neutralize any acid that might spill. Separate damaged and intact batteries. Nickel-based Batteries

Nickel-based batteries have no transport limitations, however, some of the same precautions apply as for lead acid in terms of packaging to prevent electrical shorts and safeguard against fire. Regulations prohibit storing and transporting smaller battery packs in a metal box. If there is a danger of an electrical short, wrap each battery individually in a plastic bag. When carrying small batteries in your pocket, do not mix them with coins and house keys. Lithium-based Batteries

In 2009, 3.3 billion Li-ion batteries were transported by air. Such air shipment is an ongoing concern, and an airline-pilot union has asked the Federal Aviation Administration (FAA) to ban them on passenger aircraft. From March 1991 to August 2010, batteries and battery-powered devices caused 113 recorded incidents with smoke, fire, extreme heat or explosion on passenger and cargo planes. The Portable Rechargeable Battery Association (PRBA) is aware of possible hazards and opposes any revisions in transportation rules, arguing that the restrictions would cost shippers and manufacturers billions of dollars.

PRBA is made up of major battery manufacturers, including Energizer, Panasonic, SAFT America, Sanyo and Varta Batteries. These manufacturers do not want to disrupt air shipments, especially batteries for critical medical and military missions. They argue that the batteries causing problems do not meet US hazardous material handling regulations and ask the FAA to enforce stricter manufacturing rules. The manufacturers tell the aviation industry further that, as a result of the well-publicized 2006 recall, a safer generation of Li-ion batteries has emerged. According to U.S. Census Bureau (2010), airfreight transports roughly 364 million cell phones, 142 million cameras and 47 million laptops as part of just-in-time delivery to stores. No deaths and only 26 injuries are attributed to shipping billions of lithium batteries every year.

The estimated failure rate of Li-ion is one per 10 million. Examining the 113 recorded incidents of transporting batteries by air in 19 years reveals that most failures occurred due to inappropriate packaging or handling, which caused damage or electrical short. Most incidents happened at airports or in cargo hubs. Problem batteries include primary lithium (lithium-metal), lead, nickel and alkaline systems, and not just lithium-ion, as is perceived. Newer consumer products have very few surprise failures caused by Li-ion batteries.

There are, however, restrictions with lithium-ion batteries on airplanes and travelers are reminded how many batteries can be carried on board in portable devices and as spare packs. Since January 2008, people can no longer pack spare lithium batteries in checked baggage, but airlines allow them as carry-on. The passenger compartment enables better safety monitoring with access to fire extinguishers. In one incident, a coffee pot served as extinguishing device for a flaming laptop battery on board of a plane. This would be impossible in the cargo bay below.

In terms of transportation, lithium-based batteries are divided into non-rechargeablelithium-metal batteries that are typically used in film cameras, and the rechargeable lithium-ion battery found in cell phones and laptops. Airlines allow both types as carry-on either installed or carried as spare packs as long as they don’t exceed the following limitation of lithium or equivalent of :

2 grams for primary lithium batteries

8 grams for a secondary lithium-ion. This amounts to a 100Wh battery.

25 grams for all Li-ion combined. This amounts to 300Wh worth of Li-ion batteries.

The lithium content of the primary lithium batteries is often printed on the label. Li-ion, on the other hand, has no metallic lithium and uses the equivalent lithium content (ELC) instead. To calculate the ELC, multiply the rated capacity (Ah) times 0.3. As an example, a 1Ah cell has 0.3 grams of lithium. The 8-gram ELC limitation allows a 100Wh battery.

A laptop battery commonly uses 2Ah cells containing 0.6 grams of ELC each. The battery pack may have eight cells (4 in series ; 2 in parallel), which brings the ELC to 4.8 grams, well below the 8-gram limit allowed by a single pack. To derive the watt-hour, multiply the battery voltage by the ampere-hours (Ah). The battery in question has a voltage of 14.40V (4 x 3.6V) and a rating of 4Ah (2 x 2A). In summary, 14.4 x 4 = 57.6Ah, or roughly 60Wh.

While regulations limit the Li-ion battery to no larger than 100Wh, each passenger and travel companion is allowed to carry spare packs of up to 25 grams of ELC, or 300Wh. The airlines recommend placing each battery in a clear plastic bag or covering the contacts with a tape to prevent an electric short. Although current rules forbid passengers from carrying lithium-ion batteries in checked luggage, devices with non-removable batteries, such as the iPhone, iPad and certain brand of laptops, are exempt from the rules.

Anyone shipping lithium-ion batteries in bulk must meet transportation regulations and this applies to domestic and international shipments by land, sea and air. Lithium-ion cells whose equivalent lithium content exceeds 1.5 grams or 8 grams per battery pack (100Wh) must be shipped as “Class 9 miscellaneous hazardous material.” Film crew often carry larger batteries for professional video cameras, and these are handled as hazardous material. If a shipment in the US contains more than 24 lithium cells or 12 lithium-ion packs, special markings and appropriate shipping documents are required. Each package must be clearly marked to inform the airline that lithium batteries are involved. Open cells and packs must be separated to prevent electrical short. The packages must be strong to allow stacking. Frequently Asked Questions about Transporting Lithium Ion Batteries by Air

Must consumer-type lithium ion batteries always be shipped as Class 9 dangerous good ?

No. Almost all small Li-ion (less than 100Wh) in consumer products are except from dangerous goods regulations and do not require Class 9 labeling, marking or packaging.

In what quantities can lithium ion batteries be shipped ?

Lithium ion batteries can be shipped in small and large quantities. A single package may contain as few as five batteries, while a pallet may contain more than 1,000 packs.

Why do some packages of Li-ion batteries contain a "Caution" marking and include shipping papers when most consumer lithium ion batteries are except from regulation ?

In the US, the marking is mandatory for packages of more than 24 Li-ion cells or 12 Li-ion packs. The documents identify the goods and tell what to do if the package is damaged.

Must lithium ion batteries be tested according to the UN Manual of Tests and Criteria ?

Yes, all Li-ion cells and packs shipped internationally must be tested. In the US, UN testing also includes small, consumer-size lithium ion cells and packs. Read about Building a Lithium-ion Pack.

To assure lithium-based batteries are designed and packaged to withstand transportation conditions, the US Department of Transportation (DOT) proposes new regulations. While the Airline Pilots Association supports tighter restrictions and has called for lithium batteries to be “fully regulated dangerous goods” as airline cargo, PRBA recommends dropping the proposed rules in favor of the International Civil Aviation Organization requirement (ICAO), which has been in effect since 2009 but was never applied in the US. Industry lobbyists say that the government has enough rules to ensure safe battery shipments and express concern that some shippers do not follow packaging requirements. They recommend stronger enforcements there. Proposed changes by the US Department of Transportation (DOT

Mandate that all batteries pose a hazard when transported.

Mandate transport documentation to accompany a shipment of small lithium batteries, including notifying the pilot of the location of Li-ion being shipped on the aircraft.

Require manufacturers to retain UN-specified tests for all lithium battery types transported.

Make cargo locations accessible to crew, place cargo in locations equipped with an FAA-approved fire suppression system, or transport cargo in an FAA-approved container.

Adopt watt-hours formula in place of equivalent lithium content.

Put Li-ion not exceeding 100Wh in inner package of 10kg (22lb) limit ; attach caution label.

Divert the transportation of defective or damaged batteries to highway, rail and boat.

DéQuonoPhone (DQP)

DéQuonoPhone (DQP)